Designed for ATV’s, mopeds, chainsaws, mini-bikes, scooters or go-karts, as well as numerous industrial applications, centrifugal clutches are custom built to suit the requirements of the application and include various coupling, flywheel, pulley, universal shaft and soft start combinations.

We supply new or refurbish existing centrifugal clutches to individual requirements and our experienced team ensures that they are fit for the job at hand. We can also make recommendations to enhance the function of an existing centrifugal clutch application using our wide experience in this field.

Our clutches are built to last and are engineered to provide long service life, over the past 40 years we have been providing quality industrial clutches to companies of all sizes including blue chip clients like Corus UK and Railtrack as well as individual enthusiasts and small businesses to whom we offer a counter service or delivery through the courier network.

How It Works

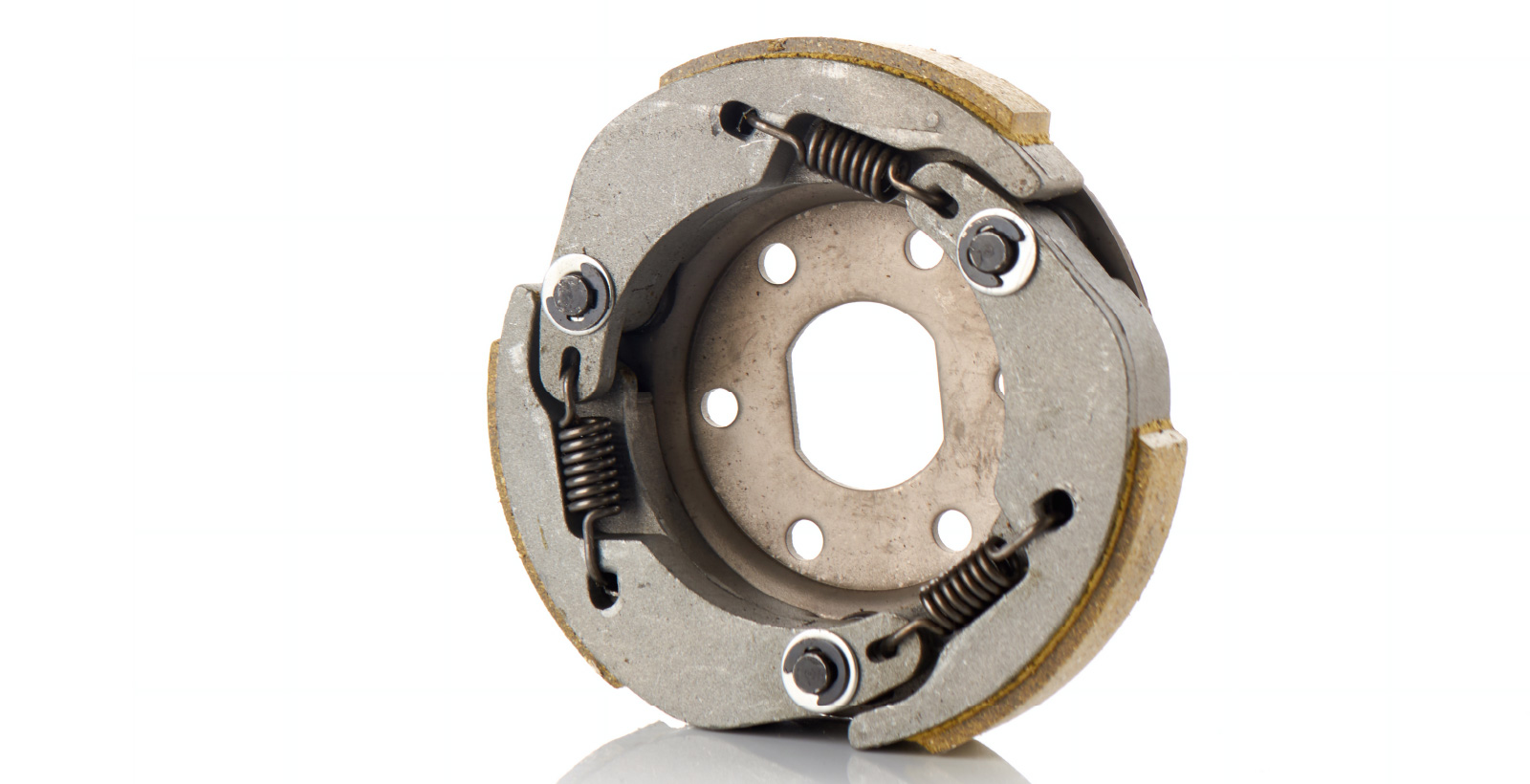

Centrifugal clutches work using the principle of centrifugal force (pushing outwards from the centre) to throw out spring-loaded arms, mounted in a radial configuration on an inner rotating shaft, normally directly connected the crankshaft of an engine. On these arms friction material is bonded or riveted to the outer faces and acts against an inner (drum) type face, transferring drive to from the inner to outer shaft as engine revolutions increase.

They are popular in simple, gearless vehicles or machines as they do not require a separate clutch operating mechanism. The springs can be changed to adjust the revolutions required for engagement of the clutch as they act against the radial force to retain the arms and as revolutions decrease pull them back to effect disengagement.

Get In Touch

Please feel free to get in touch with us to discuss your centrifugal clutch requirements on 02920 499111 or [email protected] and we would be happy to be of assistance.