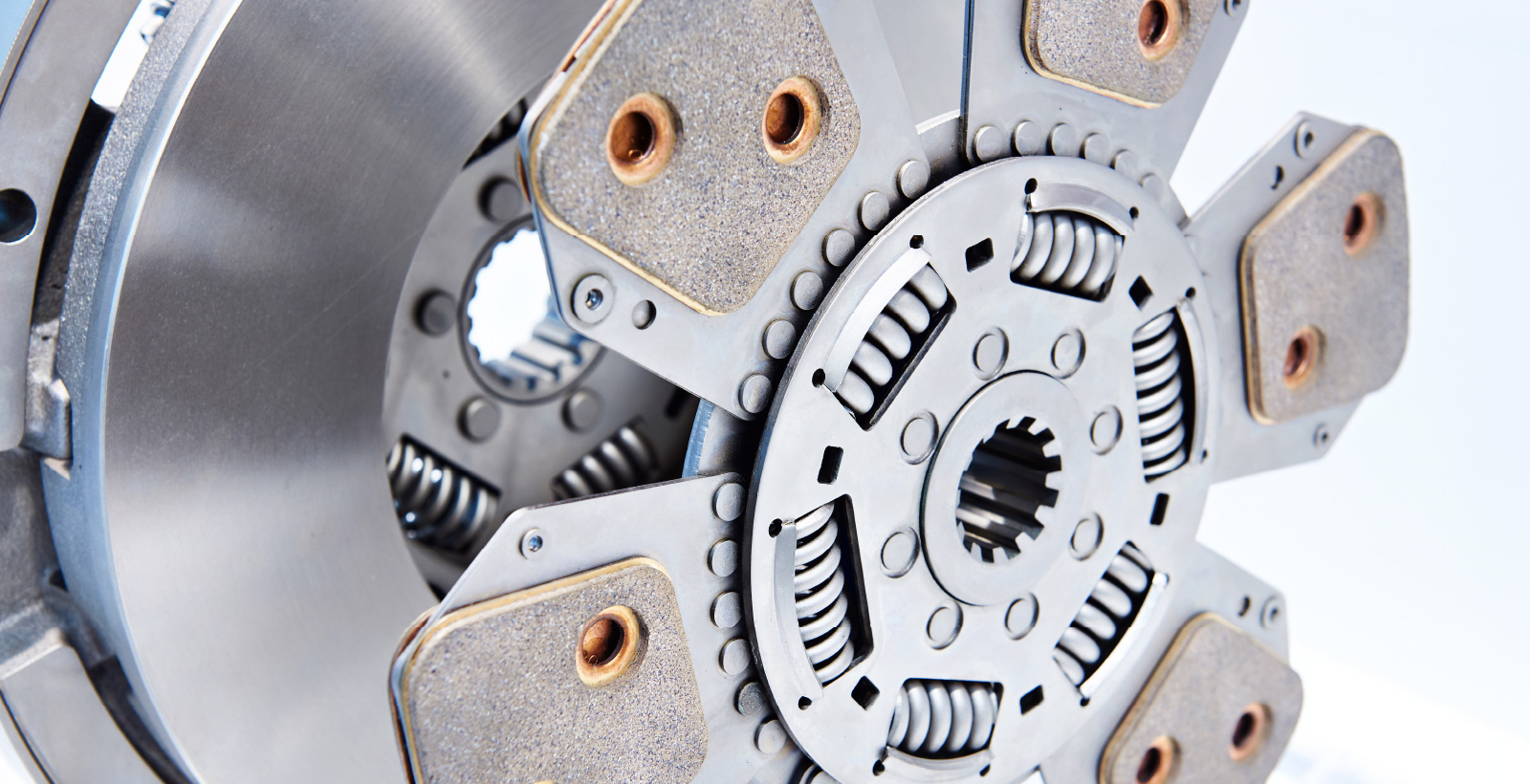

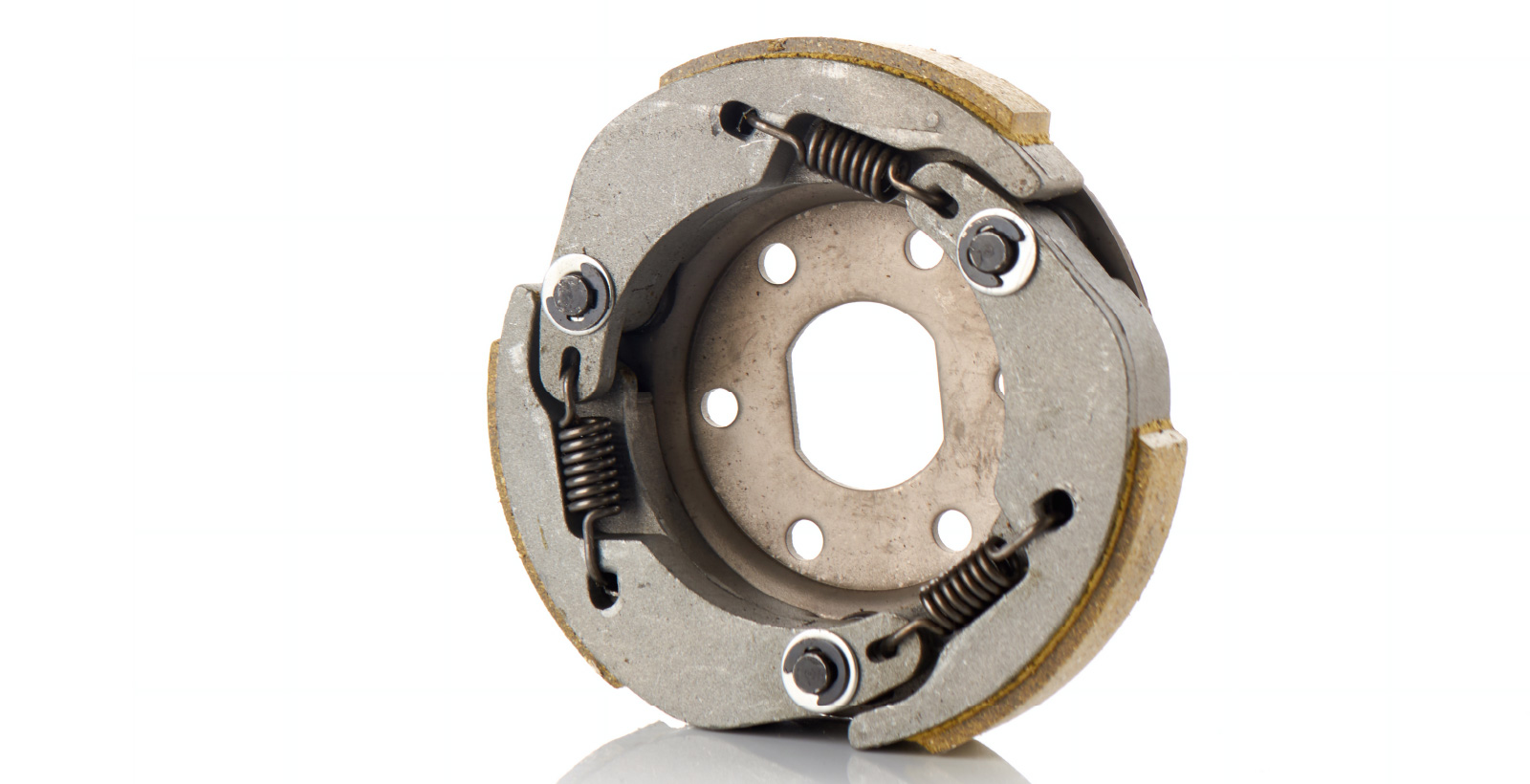

Industrial Friction Materials clutch relining services will reline any kind, size or type of clutch from a small centrifugal sewing machine clutch to a large 14” tractor disc clutch plate. There are many other types of clutch we refurbish such as paddle & cone clutches etc. The refurbishment service includes the removal of the old linings, thorough cleaning & surface preparation, the fitting of the clutch lining material which uses thermal bonding, riveting or if required both processes. We also use the highest quality in friction materials currently available. Our clutch relining services offer higher strength & durability than our competitors and can often make improvements over OE specifications.

We have decades of experience in friction applications and can make recommendations to improve aspects of the performance, wear rate or resolve clutch engagement issues. To improve turn-around time, we carry large stocks of various clutch linings in various sizes and materials to keep the downtime of your vehicle or machine to a minimum.

Although we are based in South Wales, we offer our clutch relining services to clients across the nation. We ensure that you are 100% happy with our clutch reline work and you get the very best service from our employees who have many years experience in the industry.

Where we supply

- Aerospace Industry

- Forestry & Timber Industry

- Maritime Industry

- Agricultural Industry

- Food & Dairy Industry

- Paper & Pulp Industry

- Aerospace Industry

- Forestry & Timber Industry

- Maritime Industry

- Agricultural Industry

- Food & Dairy Industry

- Paper & Pulp Industry